The U.S. aviation industry stands at a crossroads. As President Donald Trump emphasized the importance of reinvigorating manufacturing jobs within the country, a pressing reality looms: an acute shortage of skilled labor in aviation. The average age of certified aircraft mechanics is a telling statistic: 54 years. Moreover, a staggering 40% are over 60. This demographic crisis is not just a minor inconvenience; it’s an existential threat to the aviation industry’s future. Reports predict a shortfall of 25,000 aircraft technicians by 2028, a void that if not addressed, could cripple an already fragile industry.

The aging workforce, many of whom entered the sector during a booming aviation era in the ’80s and early ’90s, is ideally positioned for retirement. Unfortunately, this is happening just as the industry is beginning to recover from the catastrophic downturn induced by the COVID-19 pandemic. We saw a mass exodus of talent as companies slashed jobs, either by offering early retirement or opting for buyouts to experienced personnel. The impact of these decisions is manifesting in longer wait times for aircraft repairs and maintenance, which ultimately affects the safety and reliability of air travel.

Wage Wars and Retention Struggles

Despite the aerospace industry’s potential for lucrative salaries—with average annual earnings for aircraft technicians hitting nearly $80,000—recruitment efforts are hampered by a lack of awareness and interest in these roles among younger populations. It’s disheartening to see that even in a sector where pay can reach upwards of $130,000 for experienced staff, young people might still prefer traditional four-year degrees over vocational training. The reality is that many prospective technicians are not even aware that careers in aviation provide a pathway to stable employment.

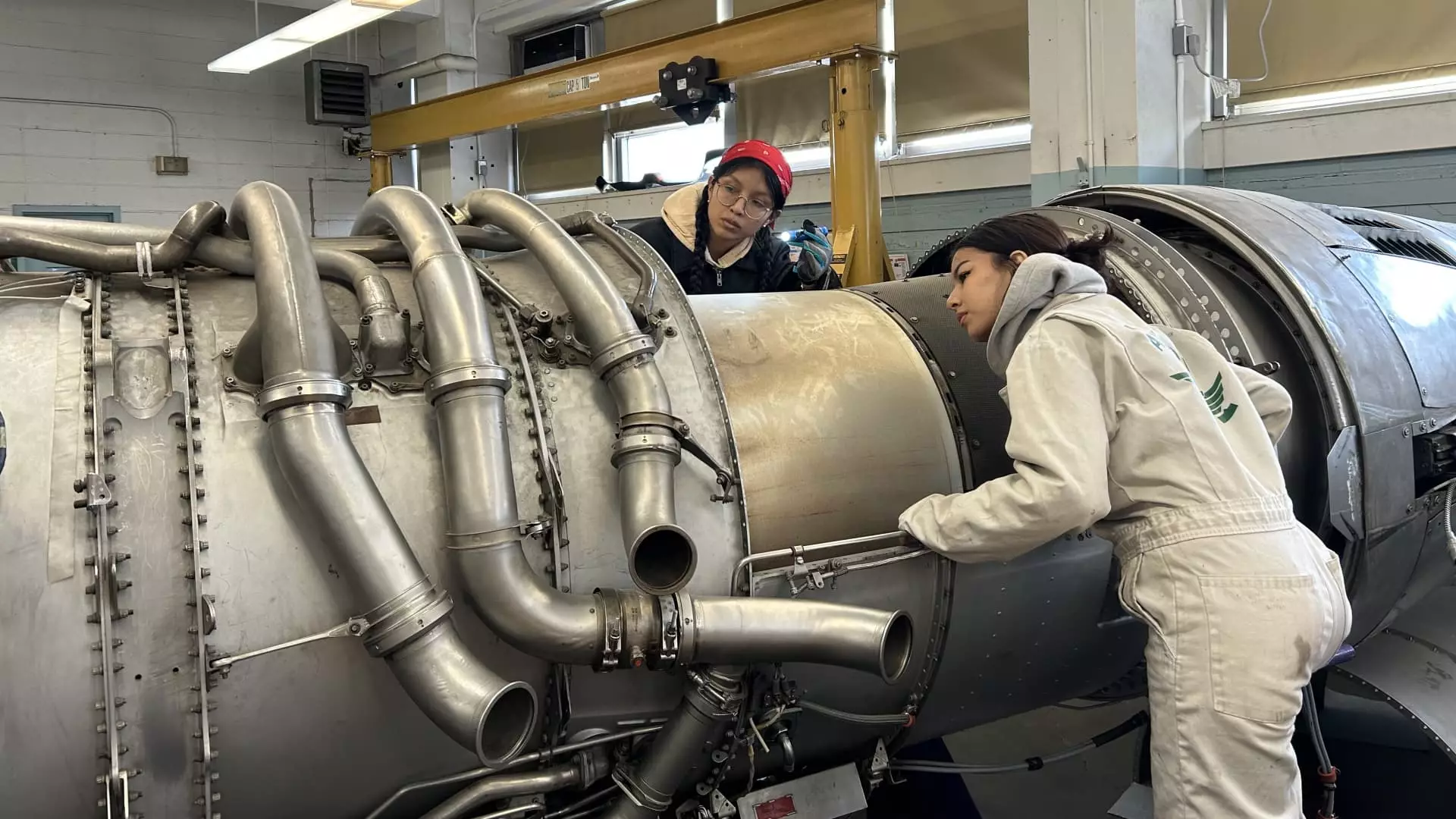

Addressing these outdated perceptions and enticing younger workers has become critical. Organizations like GE Aerospace have recognized the urgency of this situation and are beginning to ramp up hiring and retention strategies, a necessary but reactive measure to an ongoing issue. The willingness of students like Sam Mucciardi, a senior from Aviation High School in Queens, New York, to dive firsthand into aviation mechanics signals a potential turning tide, but we need many more like him to ensure a workforce that can support the industry’s demands moving forward.

Why Manufacturing Jobs Still Matter

The fascination with manufacturing jobs in America stems from their economic importance and potential for job creation. Manufacturing encompasses 9% of U.S. employment, yet this figure belies deeper issues. Gordon Hanson’s assertion that the labor market’s geographical immobility hampers hiring efforts rings true. When factories reopen or new manufacturing hubs emerge, we may find ourselves grappling with local labor shortages that threaten to stall economic progress.

Yet beyond the figures lies an opportunity to reshape perceptions surrounding manufacturing roles. High-tech advancements in the sector—the use of precision machinery, satellite technology for navigation, and advancements in engine design—position manufacturing as an innovative field that appeals to the tech-savvy youth of today. It’s time for parents, educators, and industry leaders to advocate for this shift in mindset, illustrating that a career in aviation can lead to a stable and rewarding life, in a high-tech environment that contributes to America’s economic prowess.

The Way Forward: Collaborative Efforts

The path ahead for the aviation industry lies in collaboration among schools, universities, and companies. Initiatives such as GE’s apprenticeships and American Airlines’ outreach to high schools are steps in the right direction. These partnerships can facilitate better training, provide real-world experience, and generate awareness among students about career opportunities that might otherwise go unnoticed.

But we must also recognize that a simple increase in wages is not the panacea for the industry’s woes. Sarah MacLeod’s call for heightened wages is valid, yet the focus needs to extend beyond just financial incentives. We must invest in creating an environment and culture that promotes aviation jobs as not only viable options but desirable careers. Industry leaders must actively engage in redesigning curricula to integrate new technologies and practices, and mentoring programs should be established to help young technicians navigate their early careers.

In an age where political discourse often paints manufacturing as a relic of the past, America’s aviation sector stands as a testament to the potential of skilled labor. The imminent workforce shortages should provoke a serious reconsideration of how we cultivate interest, appreciation, and investment in this critical field. Regardless of political leanings, fostering a robust, skilled aviation workforce is vital not just for the industry, but for the very fabric of American innovation and economic stability.